The ComMarker Omni 1 UV laser engraver is a powerful 5W desktop system designed for engraving plastics, wood, metals, glass, stone, and even organic materials. But if you’ve used it in LightBurn, you’ve probably noticed something unusual: many parameters (such as power) are greyed out.

Unlike CO₂ or fiber lasers, the Omni 1 relies primarily on two key controls:

-

Frequency (kHz) – how many laser pulses per second are delivered.

-

Q-Pulse width – the duration of each pulse, controlling the energy per shot.

By mastering these two settings, you can achieve consistent, clean, and professional-quality results across a wide range of materials. This guide provides step-by-step references for 16 common materials, adapted from both real-world testing and community insights.

Why Material Settings Matter

-

Precision & Contrast: UV lasers interact differently depending on material type. Too much energy causes burning or cracks; too little leaves faint marks.

-

Productivity: Optimized frequency and Q-pulse shorten cycle time while maintaining quality.

-

Durability: Correct settings reduce wear on optics and extend your engraver’s lifespan.

-

Safety: Controlled passes and proper focus minimize fire hazards and toxic fumes.

Before You Start

-

Clean the work surface and secure material flat.

-

Focus carefully with the Omni 1’s red dot and motorized Z-axis.

-

Ventilate using the built-in exhaust fan or an external air filter.

Key Laser Parameters Explained

-

Speed (mm/s): Head movement speed. Higher speeds reduce heat marks but may lighten engraving.

-

Frequency (kHz): Pulse repetition rate. Higher frequency = smoother edges, especially on plastics/metals.

-

Q-Pulse width: Pulse duration. Longer pulses = more energy per shot, ideal for metal or leather.

-

Passes: Multiple light passes usually give better results than a single heavy one.

-

Line Interval (mm): Raster spacing. Tight intervals (0.03 mm) give sharper resolution.

-

Image Mode (LightBurn only): Enables dithering for grayscale or 2.5D effects.

Recommended Settings by Material

(Machine: Omni 1 UV 5W · Software: LightBurn)

1. Clear Acrylic Engraving

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 1000 mm/s

-

Passes: 1

-

Line Interval: 0.03 mm

💡 Back-engrave for a frosted glass look. Mask the back with painter’s tape to prevent smoke marks.

2. Acrylic Leaf Pattern (with dithering)

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 500 mm/s

-

Line Interval: 0.03 mm

-

Image Mode: Atkinson

💡 Atkinson dithering gives smooth gradients; keep interval tight for fine leaf veins.

3. Glass Ornaments

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 200 mm/s

-

Passes: 1

-

Line Interval: 0.03 mm

💡 Use a damp paper towel or dish soap film to reduce micro-fractures.

4. Coconut Shell

-

Frequency: 30 kHz

-

Q-Pulse: 1

-

Speed: 500 mm/s

-

Passes: 1

💡 Lightly sand first; shells vary, so test on a scrap piece.

5. Leather Badges (Engrave + Cut)

-

Engraving Pass: 30 kHz / Q-Pulse 20 / 1000 mm/s

-

Cutting Pass: 40 kHz / Q-Pulse 1 / 100 mm/s / 5 passes

💡 Always engrave first, then cut. Use vegetable-tanned leather for best contrast.

6. MDF 4 mm Cutting

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 75 mm/s

-

Passes: 10

💡 Use multiple passes to avoid heavy charring; vacuum debris every 2–3 passes.

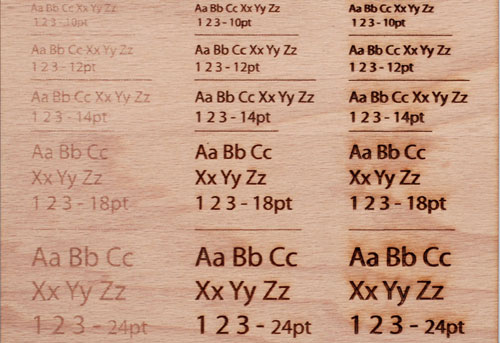

7. Wood (Engraving + Cutting)

-

Engraving: 40 kHz / Q-Pulse 1 / 200 mm/s / 3 passes

-

Cutting: 30 kHz / Q-Pulse 1 / 50 mm/s / 6 passes

💡 Crosshatch fill creates textured signs; birch plywood works consistently.

8. Rice Grain Micro-Engraving

-

Frequency: 40 kHz

-

Q-Pulse: 15

-

Speed: 100 mm/s

💡 Fix grains with double-sided tape; high Q-pulse ensures visible micro text.

9. Plastic Earbud Case

-

Frequency: 40 kHz

-

Q-Pulse: 15

-

Speed: 1000 mm/s

💡 Cover with light masking tape to reduce melt lines. Fast speed prevents distortion.

10. Rotary Glass Bottle Engraving

-

Frequency: 40 kHz

-

Q-Pulse: 5

-

Speed: 600 mm/s

-

Passes: 2

💡 Secure bottle in rotary tool. Apply clear coat afterwards for durability.

11. Towel (Textile Engraving)

-

Frequency: 30 kHz

-

Q-Pulse: 17

-

Speed: 2500 mm/s

💡 Use 100% cotton; one fast pass prevents scorching.

12. Paper / Cardboard Cutting

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 100 mm/s

-

Passes: 3–5

💡 Tape both sides to avoid burn-through. Works best on 200–300 gsm stock.

13. Metal Bottle Opener

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: ~830 mm/s

💡 Clean with alcohol first. Seal with clear coat for abrasion resistance.

14. PU Leather Shoes

-

Frequency: 30 kHz

-

Q-Pulse: 20

-

Speed: 1000 mm/s

💡 Test on a hidden seam first; higher Q-pulse increases contrast.

15. Slate Coasters

-

Frequency: 40 kHz

-

Q-Pulse: 1

-

Speed: 1000 mm/s

💡 One clean pass produces bright contrast without surface flaking.

Final Tips

-

Always test on scrap material first.

-

Adjust frequency and Q-pulse in small steps—they have the biggest impact on results.

-

Keep optics clean and check focus regularly.

The Omni 1 UV laser engraver might feel limited in LightBurn, but by mastering just two controls—frequency and Q-pulse—you unlock its full engraving potential. With the right settings, you can produce crisp holiday ornaments, fine text on metals, or detailed organic patterns with professional consistency.