Cutting metal—especially stainless steel—can be challenging even with a powerful fiber laser engraver. Many users attempt to cut thin stainless-steel sheets and find that although the laser penetrates the surface, the parts won’t separate, edges fuse back together, or the entire sheet bends from excess heat.

A user recently attempted to cut 1 mm stainless steel on a fiber laser. Even though the beam fully penetrated the plate, the numbers could not be removed. Multi-pass attempts caused severe deformation, and wobble mode only helped partially—leaving sharp edges and a warped sheet.

If this sounds familiar, this guide walks you through why this happens and the exact method recommended to cut metal cleanly using a fiber laser.

Why Does Stainless Steel Melt Back Together When Cutting?

Fiber lasers have extremely high energy density. When cutting metal:

-

The beam melts the steel along the cut path

-

The molten metal re-solidifies rapidly

-

If the gap is too thin, both sides fuse back together

-

Excess heat causes the sheet to bend or warp

This is why a single outline cut usually fails—

you melt the line, but the molten metal immediately re-welds itself.

To prevent this, you need a wider heat-removal channel instead of a single cut line.

That is exactly what the offset cutting method solves.

How to Cut Stainless Steel Successfully Using a Fiber Laser

We recommend using the offset + fill cutting strategy instead of direct outline cutting. This removes material between two lines so the steel cannot melt back together.

Below is the recommended solution.

Step-by-Step Method for Clean Fiber Laser Metal Cutting

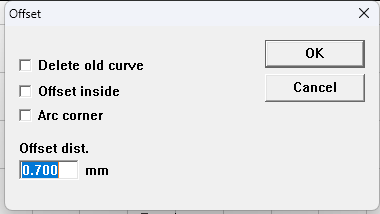

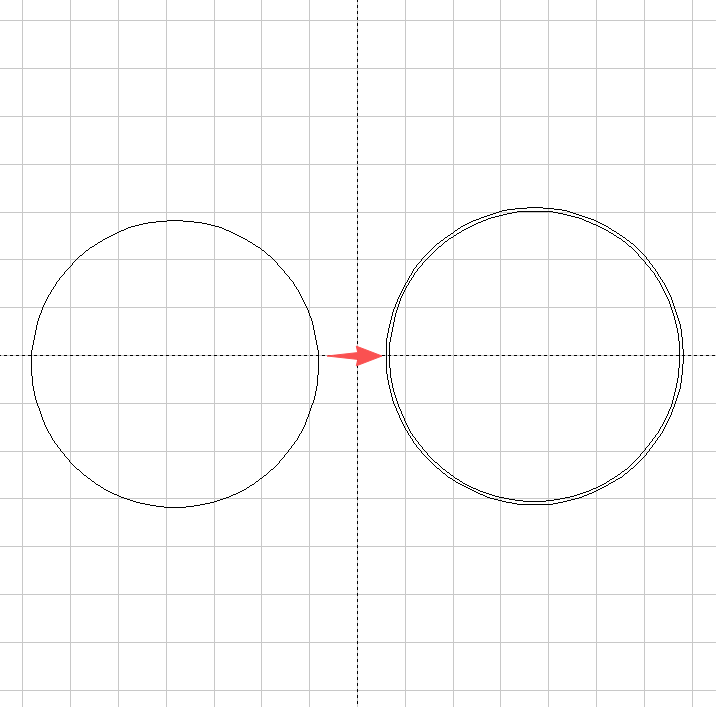

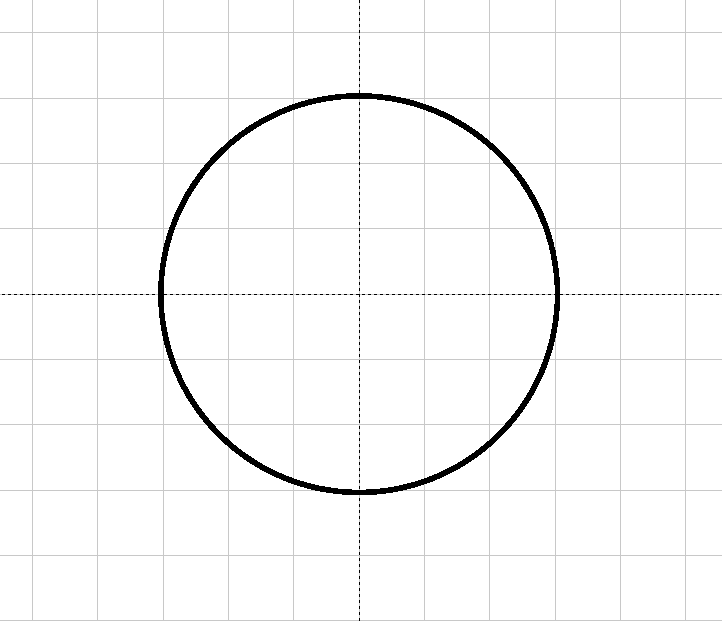

1. Use the Offset Function (EzCad or LightBurn)

This creates a second outline that widens the cutting groove.

In EzCad:

-

Click Edit → Offset

-

Set Offset Distance: 0.7 mm (recommended)

-

A new outline will appear outside the original path

-

Select both outlines for filling

This ensures cutting removes a strip of metal instead of dragging a single line.

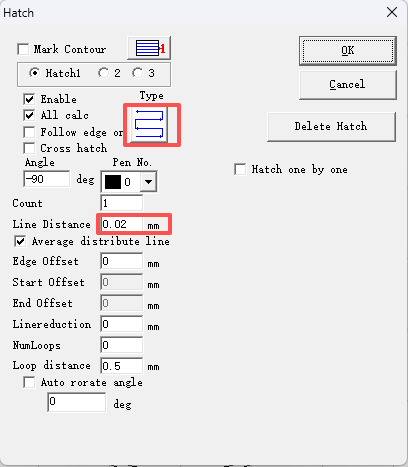

2. Set Fill Mode to “Double-Line Fill”

This is essential.

-

Fill Type: Double Line

-

Line Spacing: 0.02 mm

The laser then engraves away the metal between the two outlines, creating a clean separation channel.

3. Recommended Fiber Laser Cutting Parameters

For stainless steel cutting on a fiber laser:

| Setting | Value |

|---|---|

| Speed | 100 mm/s |

| Power | 95 % |

| Pulse Width | 200 us |

| Frequency | 40 KHz |

These values maximize penetration while reducing heat concentration and warping.

Why This Method Works

The offset-cut approach:

-

Removes metal instead of melting a single thin line

-

Prevents molten edges from re-joining

-

Produces smoother, detachable pieces

-

Reduces sheet warping

-

Works much better for stainless steel cutting than outline-only passes

Users who tried this method reported that the cut pieces lifted out cleanly with minimal resistance.

Tips for Better Metal Cutting on Fiber Lasers

-

Use a stable metal fixture to prevent vibration

-

Avoid too many high-power single passes

-

Let the metal cool between passes

-

Increase offset for thicker sheets

Conclusion

If your fiber laser penetrates stainless steel but the pieces refuse to separate—or the sheet warps heavily—then you’re likely using outline cutting, which always causes molten metal to re-fuse.

Using offset cutting + double-line fill with the right parameters is the correct and most reliable method for cutting stainless steel with a fiber laser engraver. This produces cleaner cuts, smoother edges, and far less heat deformation.