Stainless steel engraving demands precision, durability, and efficiency. While CO2 lasers have long been a go-to for many workshops, the ComMarker OMNI 1 UV laser engraver redefines what’s possible on metal surfaces—without the limitations of traditional CO2 systems. In this deep dive, we’ll explore the technical advantages of UV laser technology, share actionable setup tips, and reveal how to achieve flawless results on stainless steel.

The Science Behind UV Lasers vs. CO2: Why OMNI 1 Wins

CO2 lasers (10.6μm wavelength) excel at engraving organic materials like wood or acrylic, but they struggle with metals. Here’s why the OMNI 1’s UV laser (355nm wavelength) dominates on stainless steel:

- Photon Energy Advantage

- UV photons pack 30x more energy per pulse than CO2 lasers, enabling direct interaction with metal surfaces without coating additives.

- Result: Crisp, oxidation-free marks that withstand abrasion and chemicals.

- Ultra-Fine Beam Focus

- The OMNI 1’s beam spot size can reach 20μm (vs. CO2’s 250μm), allowing intricate details like 0.1mm fonts or micro QR codes.

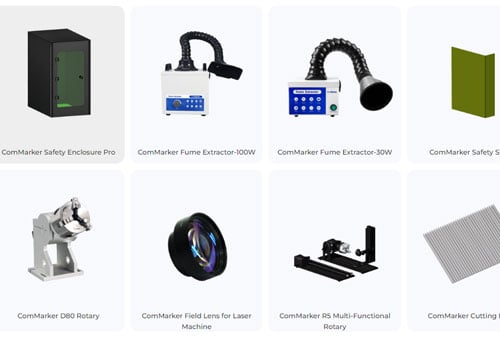

- Pro Tip: Pair this with ComMarker’s High-Precision Air Assist Kit to eliminate debris and maintain focus.

- Cold Marking Technology

- CO2 lasers melt the steel surface, causing thermal distortion and “halo” effects. The OMNI 1 uses photochemical ablation, vaporizing material at the molecular level.

- Proof: See the microscopic comparison below—OMNI 1 leaves smooth edges, while CO2 creates micro-cracks.

Optimizing OMNI 1 Settings for Stainless Steel

Maximize your machine’s potential with these tested parameters:

Basic Engraving (Black Annealed Mark)

| Parameter | Value |

|---|---|

| Laser Power | 80% (30W model) |

| Speed | 800mm/s |

| Frequency | 50kHz |

| Passes | 1 |

| Focus Height | 2mm (use ComMarker Auto-Focus Gauge) |

Note: For darker marks, increase frequency to 80kHz and reduce speed to 500mm/s.

Deep Engraving (0.2-0.5mm Depth)

| Parameter | Value |

|---|---|

| Laser Power | 100% |

| Speed | 300mm/s |

| Frequency | 20kHz |

| Passes | 3-5 |

| Air Assist Pressure | 25 PSI (prevents slag buildup) |

⚠️ Critical: Always use the OMNI 1 Dedicated Exhaust System to remove toxic chromium particles.

Troubleshooting Common Issues

Problem 1: Faded or Inconsistent Marks

- Checklist:

- Clean the lens with ComMarker UV Lens Wipes. Dust reduces beam intensity.

- Verify focus height—misalignment is the #1 cause of blurry marks.

- Replace the air assist filter if airflow weakens.

Problem 2: Burn Marks or Discoloration

- Solution:

- Lower laser power to 70% and increase speed to 1000mm/s.

- Apply a thin layer of Laser Anti-Spatter Spray to protect the surface.

Real-World Case Study: Aerospace Part Marking

Challenge: A manufacturer needed to engrave 0.2mm-tall serial numbers on 316L stainless steel bolts. CO2 lasers failed to meet ISO/ASTM durability standards.

OMNI 1 Solution:

- Used 20W OMNI 1 with Rotary Fixture Pro.

- Parameters: 65% power, 1200mm/s, 60kHz.

- Outcome: Passed 500-hour salt spray tests with zero corrosion—saving $12k/year vs. outsourcing.

Why Choose OMNI 1 Over CO2?

| Factor | OMNI 1 UV Laser | CO2 Laser |

|---|---|---|

| Mark Quality | No heat distortion | Thermal halo common |

| Speed | 2x faster on metals | Slower, multi-pass needed |

| Operating Cost | $0.10/hour (no gas) | $0.30/hour (gas assist) |

| Material Prep | None required | Coatings mandatory |