ComMarker has done it again. With the launch of the Omni X UV Laser Engraver, the brand listened closely to what creators and professionals have been asking for — and delivered a model packed with real, user-driven upgrades.

From vitrography (3D glass engraving) to a fully enclosed housing, an auto-focus system, and the ability to engrave objects up to 400 mm, the Omni X redefines precision engraving for small businesses, artists, and DIY enthusiasts alike.

In this review, I’ll share my hands-on experience testing the Omni X — from setup to glass engraving, wood detailing, and 3D crystal art. Let’s find out if this UV laser engraver is just a high-tech toy or a serious professional tool.

Unboxing and First Impressions

The Omni X arrived in a large, well-protected package. Inside, I found the laser itself, all necessary cables, and two lenses — 70 × 70 mm and 150 × 150 mm. These cover different engraving fields depending on your project type: fine crystal engraving or larger surface designs.

ComMarker also includes a movable Z-axis and an optional motorized worktable that extends the X-axis, allowing engraving on materials up to 400 mm in size. The setup was straightforward, and everything felt solid and well-engineered.

What Makes a UV Laser Engraver Special?

Both the Omni 1 and Omni X are Galvo-based UV Laser Engravers — meaning they use high-speed mirrors to direct the beam. These “cold lasers” are known for minimal heat output, incredible precision, and versatile surface compatibility.

To put it into perspective:

-

Omni X laser spot size: 0.0019 mm

-

CO₂ laser: ~0.15 mm

-

Fiber laser: ~0.03 mm

-

Diode laser: ~0.1 mm

This microscopic beam allows for ultra-fine detail work — ideal for engraving delicate materials like glass, ceramics, and plastics without causing cracks or burns.

Glass Engraving Test: Clean, Sharp, and 3D-Ready

Glass is one of the trickiest materials for laser engraving, but the Omni X handled it beautifully. Unlike CO₂ or fiber lasers, the UV beam can engrave directly on glass without any coating. The surface micro-fractures smoothly, with almost no chipping or sharp edges.

By adjusting the focus depth, I was able to engrave inside the glass, not just on its surface — perfect for creating layered, 3D images. The results were stunning: crisp, detailed, and visually deep without any surface damage.

💡 Tip: Thicker glass works best. The focus can be adjusted layer by layer, enabling true 3D crystal engraving.

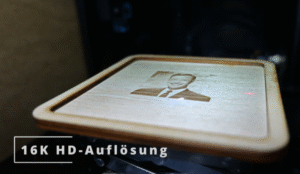

Engraving on Wood: Tiny Details, Big Results

UV lasers aren’t typically used for wood — but I was surprised. Using the ComMarker Studio software, I engraved a high-contrast black-and-white portrait generated by AI.

Without editing the file, I simply chose the preset Material: Wood and hit start. The result? Sharp, high-definition details, even in miniature scale.

Compared to diode or CO₂ lasers, the Omni X produced almost no burn marks or smoke residue. The engraving edges were clean and naturally colored — more honey-toned than burnt.

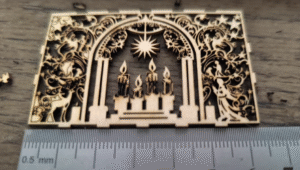

Miniature Cutting and Precision Projects

The Omni X can also perform micro-cuts up to 3–4 mm thick. Because Galvo lasers scan from a single point with mirrors, the deeper you cut, the steeper the edge becomes — which means interlocking parts might need slight adjustments.

Still, the level of precision is breathtaking. I tested it with tiny wooden model houses and seasonal decorations. The cuts were so fine and smoke-free that even miniature parts fit perfectly after minor tweaking.

Omni 1 vs. Omni X: Is It Worth the Upgrade?

If you already own the Omni 1, you’re probably wondering whether to switch. Honestly, both machines deliver exceptional engraving quality. The Omni X simply adds a few refinements — larger work area, enhanced autofocus, and quieter fans.

The price difference? Around €500 more for the Omni X. Considering the extra features and future-proofing, it’s a solid investment for professionals.

The Autofocus System: Smarter and Simpler

The Omni X UV Laser Engraver includes a LED-assisted autofocus system that automatically measures the distance between the lens and material. The measurement updates in real time, shown on a tiny side display.

If the distance isn’t correct, the system adjusts automatically — no more manual focusing or guesswork. For complex setups like 3D glass engraving, this saves huge amounts of time.

ComMarker Studio Software: Surprisingly Powerful and Free

ComMarker has introduced its own engraving software — ComMarker Studio, available for Windows and macOS. It’s intuitive, lightweight, and completely free.

Key highlights:

-

Simple layer-based design workspace

-

Tools for relief and glass engraving

-

Built-in parameter presets for different lenses

-

Password-protected device settings

-

STL (3D model) import for crystal engraving

While the German translation isn’t perfect yet, the interface is easy enough for beginners to navigate.

Creating 3D Crystal Art with a UV Laser Engraver

This was the most exciting part of my test — engraving inside crystal glass blocks. The Omni X engraves from the bottom up, building the image layer by layer. Watching the design “grow” inside the crystal is mesmerizing.

The included sample blocks (5 × 5 × 10 cm) are genuine crystal — not acrylic — since UV lasers can crack plastic. I imported an STL model (a relaxing figure sculpture) and set the Galvo speed to 1000 mm/s for maximum transparency.

After a 50-minute run, the results were breathtaking — clean, detailed, and glowing beautifully under LED light. This opens up creative potential for custom gifts, trophies, memorial keepsakes, and 3D art pieces.

A True Game-Changer for Precision Engraving

The ComMarker Omni X UV Laser Engraver isn’t a toy — it’s a precision instrument designed for creators who value detail, safety, and flexibility.

Whether you’re engraving glass, metal, wood, or crystal, this machine delivers professional results with minimal heat and smoke.

If you’re new to laser engraving or want to expand your creative possibilities, the Omni X is one of the most capable UV laser engravers you can buy right now.