Glass engraving machines are changing the world of glass crafting.

Maybe you are ready to expand an existing customize business. Add glass products like engraved wine glass or crystal jewelry, or simply increase profit for per piece you offer.

Yes, engraved glass products are in high demand and often sold at premium prices.

But, glass engraving can be a profitable business only if the production method makes sense for qualified work.

Different Glass Engraving Methods

- Rotary / Handheld Engraving Tools

Rotary engraving looks easy and cheap to get. But be aware of:

-Results depend on operator skill

-Inconsistent depth and finish

-Difficult to reproduce the same quality in batches

Turning a simple pattern into a whole afternoon of experiment.

- Sandblasting

Sandblasting is widely used in factories and workshops. However:

-Equipment is large and expensive

-Requires stencils, sand, and protective setups

-Produces a messy working environment

Once glass engraving turns into a gift business instead of a craft, these limitations become impossible to ignore.

Why Laser Engraving Is a Better Fit for Glass Businesses

Laser engraving removes many of the limits of traditional methods.

With a ComMarker laser engraving machine, you get:

-Non-contact processing, laser beam does the engraving process

-Laser system ensure consistent results

-Fast switch between different orders with Laser engraving software

-Suitable for both single pieces and batch production

It allows for consistent, high-quality results. When quality goes up, so does your profits.

Not All Laser Engravers Are Suitable for Glass

Many buyers rush into the market of laser engraving machine for glass. Picking handheld laser cutters, low-power diode lasers, or DIY laser engravers, expecting professional glass results.

But glass is unforgiving. Precision, wavelength control, and beam stability matter.

Diode laser engraver, cheap and sweet, causes

-Strong heat concentration

-High risk of cracking glass

-Rough, uneven frosting and requires messy coating

CO₂ laser engraver, large and classic,

-Limited precision for fine details

-Takes up significant workspace and bring high purchase and maintenance costs

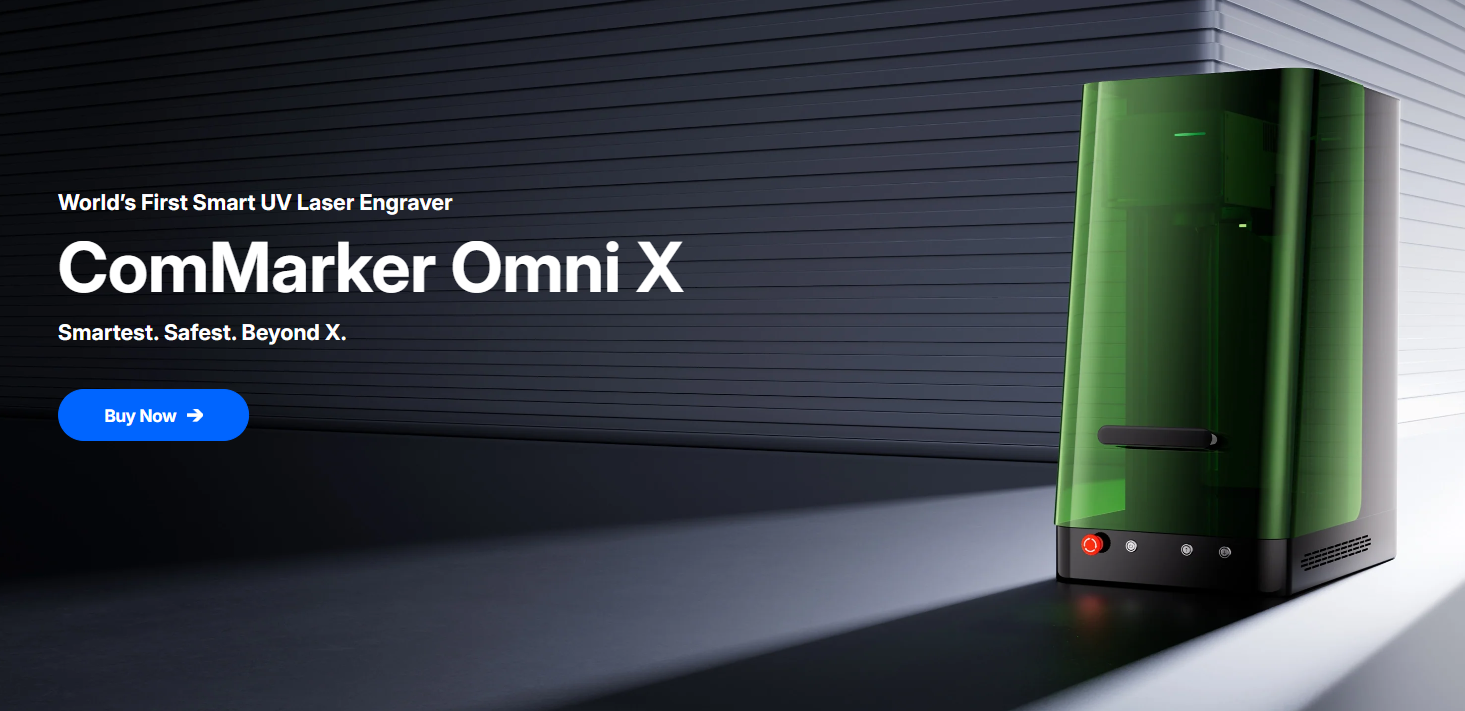

UV laser engraver, the ComMarker Omni X,

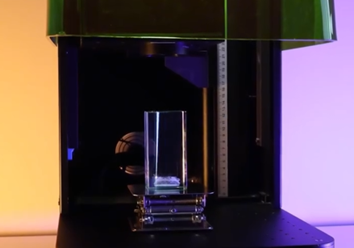

uses a 0.0019mm laser dot, engrave with 355 nm wavelength and cold marking, allows:

-Smooth, uniform frosted finishes

-No cracking on wine bottles or crystal

-Text, patterns, logo engraving, photos of lover, both surface and internal engraving

-Consistent results on curved surfaces with no need of preparing

With UV laser, you get better results and more to offer, higher standard glass, crystal, and jewelry marking.

Is UV Laser Engraving Worth the Cost?

At first glance, UV laser engravers appear more expensive than traditional tools or entry-level lasers.

But business decisions based on the outcome,

- Consumables

Sandblasting consumes abrasive materials and stencils, costing roughly $0.10 to $1.00 per cup.

In contrast, UV laser engraving’s consumables are minimal, mainly electricity costing around $0.01 to $0.03 per cup.

- Labor Cost

Sandblasting is labor-intensive and slower, with costs between $8 and $12 per piece due to manual operation and cleanup.

UV laser engraving is highly automated, taking only $0.02 half an hour and enabling faster batch processing at 10000mm/s scanning speed

- Scrap & Rework

While traditional method can cause cracks and uneven finishes, leading to higher scrap rates.

UV laser engraving produces clean, precise, and consistent results with minimal waste.

- Production Efficiency

With a UV laser, you get faster switching between different jobs and designs.

Efficient batch production with consistent, high-quality results

- Overall Unit Cost

Considering all factors, while traditional factors taking $10 to $15 per glass cup, UV laser engraving costs approximately $1.10 to $3.10

UV laser engraving reduces per-unit cost, and increases profit per piece you engrave.

Why UV Laser Engraving Produces Higher-Value Glass Products

Customers don’t pay more just because something is engraved.

They pay for:

-Clean, polished finishes

-Professional-looking photos and logos

-Premium visual texture

ComMarker Omni X UV laser engraving delivers:

-Even frosting without burn marks

-High-resolution photo engraving

-Consistent depth and clarity

-Excellent results on curved glass

Better quality doesn’t just look better, it sells better.

Compact, Desktop, and Business-Ready

Modern UV laser engravers are no longer massive industrial systems

Despite industrial-grade precision, the ComMarker Omni X is designed as a desktop laser marking machine.

You can plug it comfortably in small workshops, studios, or retail engraving shops while

-Add a rotary for engrave wine bottles

-Handle glass, crystal, leather, plastics, and coated metals

This flexibility allows businesses to expand beyond glass and create multiple revenue streams.

Typical Applications of UV Laser Glass Engraving

Engraved wine glasses

Engraved glass trophy

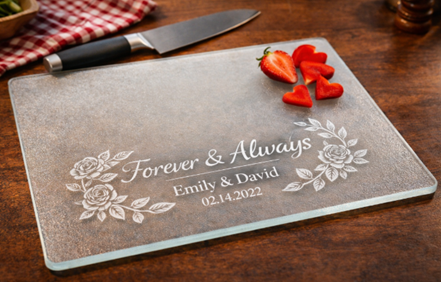

Engraved glass gifts

Photo engraving on glass and crystal

Final Thoughts: Choose the Right Starting Point

If you’re engraving glass occasionally, traditional methods may still work.

But if your goal is to:

-Sell premium glass products

-Maintain consistent quality

-Scale production efficiently

-Build a long-term business

Then UV laser engraving is not an upgrade, it’s the right foundation.

If your goal is glass engraving for profit, a UV laser engraver is the right starting point.

Choose the right machine once, and let every engraved glass piece pay you back.