Choosing the right laser source is one of the most critical decisions when buying a laser engraver. Whether you’re customizing wood gifts, marking metal tools, or personalizing glassware, your engraver’s performance—and limits—are defined by the type of laser it uses. In this article, we’ll break down the core types of laser sources (CO₂, fiber, and UV), explore their differences in wavelength and power, and help you decide which one suits your real-world needs.

What Is a Laser Source? (CO₂ vs Fiber vs UV)

A laser source in a laser engraver is the component that emits the high-energy beam used to mark or cut materials. Different source types use different physics—and that greatly affects what materials they can engrave.

| Type | Wavelength | Best for | Common Use Cases |

|---|---|---|---|

| CO₂ | 10,600 nm | Organic materials like wood, leather, acrylic | Crafting, signage, packaging |

| Fiber | 1064 nm | Metals, hard plastics | Metal tags, tools, industrial parts |

| UV | 355 nm | Heat-sensitive materials like plastic, glass, ceramics | Precision marking, electronics, medical devices |

✅ Tip: The shorter the wavelength, the better it handles fine, heat-sensitive, or brittle materials.

Why Wavelength Matters: Matching to Materials

The wavelength of the laser determines how deeply and cleanly it interacts with specific materials.

- CO₂ lasers (10,600 nm) are absorbed well by non-metals, making them ideal for engraving wood, acrylic, paper, and leather.

- Fiber lasers (1064 nm) penetrate metals effectively due to higher photon energy at that wavelength.

- UV lasers (355 nm), like those used in the ComMarker Omni 1, are absorbed on the surface without heat buildup, making them perfect for plastics, glass, and ceramics.

Power vs Efficiency: Does Higher Wattage Mean Better Engraving?

Not always.

- Higher wattage means faster marking or deeper engraving—but only when paired with the right wavelength and lens system.

- A 5W UV laser can outperform a 20W fiber laser on plastic or glass, because the UV wavelength interacts better with those materials.

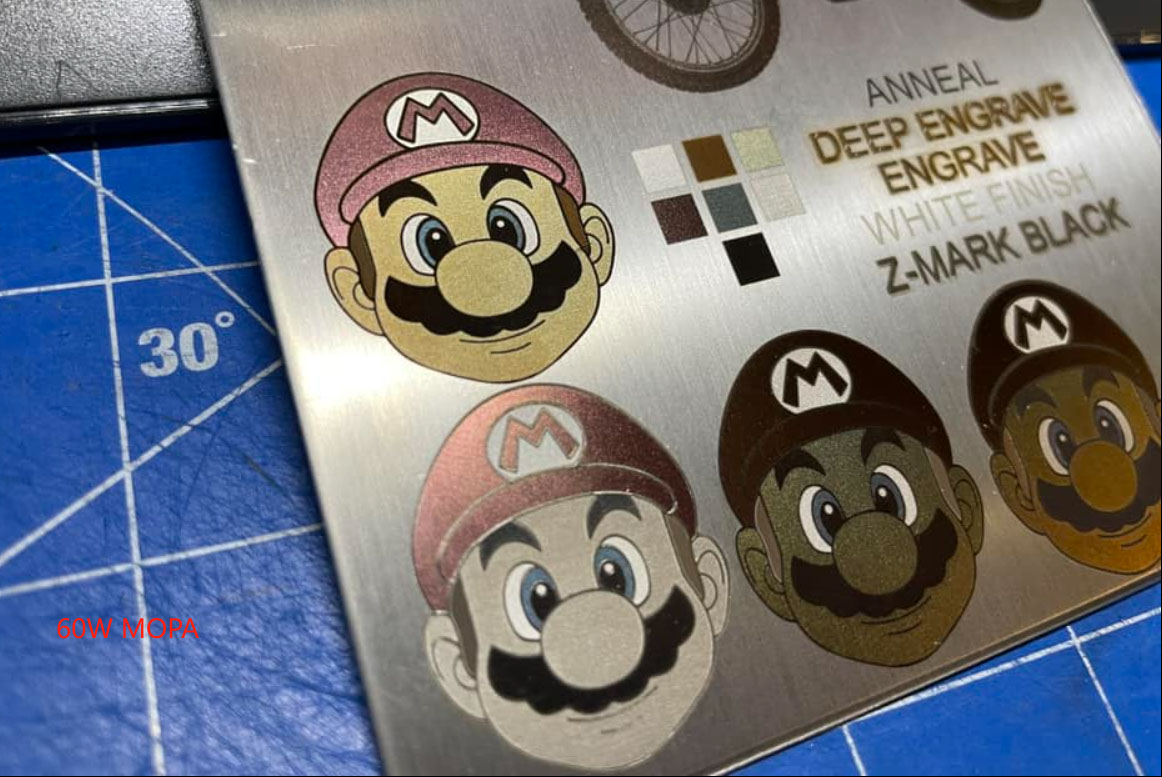

Here’s an example from real tests using the ComMarker Omni 1 UV laser engraver:

| Material | Laser Source | Power Used | Result |

|---|---|---|---|

| White ABS Plastic | UV (355nm) | 5W | High-contrast black mark, no melting |

| Stainless Steel | UV (355nm) | 5W | Light surface mark only |

| Wood | CO₂ (10,600nm) | 40W | Deep and wide engraving |

Choosing the Right Laser Source: What to Consider

When deciding which laser engraver to buy, focus on:

- Material types you work with most

- Engraving depth vs. speed (Do you need surface marks or deep cuts?)

- Level of detail (QR codes, tiny text, fine lines? UV wins here)

- Budget (CO₂ lasers are usually more affordable for hobby use)

Real-World Use Case Examples

- A jewelry crafter working with gold and silver → Go for a fiber laser

- A DIY creator customizing tumblers and wood signs → Best with a CO₂ laser

- A startup marking logos on phone cases, glasses, and ceramic mugs → Choose a UV laser, like the Omni 1

Understanding the Laser Source in a Laser Engraver: Fiber, CO2, or UV

Choosing the right laser source is one of the most crit…

Which Laser Source Is Right for You?

The best laser engraver isn’t just about power—it’s about matching the laser source to your application. If you’re engraving a variety of delicate or non-metal materials, the ComMarker Omni 1 UV laser engraver offers professional-level precision with minimal heat impact. For metals or bulk engraving, fiber and CO₂ still have the edge.

Need help choosing? Visit ComMarker.com to explore laser engravers tailored to your material needs.