Using a rotary chuck with a UV laser engraver opens up a whole new category of marking—cups, tubes, rings, tools, cylindrical parts, curved surfaces, and other items that normally can’t be engraved on a flat bed. If you’re new to rotary engraving, this guide walks you through the entire setup process based on the ComMarker workflow shown in the official video.

Whether you’re a hobbyist or running a small business, here’s how to get clean, accurate laser engraving results with a rotary chuck.

1. Prepare Your Software and Machine

Before anything else, make sure your system is ready:

-

Install ComMarker Studio on your computer

-

Connect your ComMarker Omni X/XE UV laser engraver

-

Remove the lens cap

-

Turn on the machine

These steps ensure the engraver recognizes all accessories before you switch to rotary mode.

2. Switch to Chuck Mode

Inside ComMarker Studio:

-

Disable the Door Sensor option

-

Select “Chuck Mode” in the marking mode

This tells the engraver to rotate the chuck precisely during marking.

3. Measure and Enter the Workpiece Diameter

For proper rotational alignment:

-

Measure the diameter of your object at the laser focus point

-

Enter the value into the chuck diameter setting

This ensures your design wraps around the curved surface accurately without distortion.

4. Import and Prepare Your Design

Use the left-side tools in ComMarker Studio to:

-

Import your artwork (SVG, PNG, DXF, etc.)

-

Resize or reposition if needed

Enter the correct engraving parameters for your material

Tip: Since rotary engraving wraps around a curved object, keep text spacing and height reasonable to avoid stretching.

5. Mount the Object on the Rotary Chuck

Place the workpiece securely on the chuck jaws:

-

Tighten it so it stays centered

-

Ensure the item will rotate smoothly

-

Verify the lens selection matches the physical lens on your machine

Any wobble will affect engraving accuracy, so double-check alignment.

6. Focus the UV Laser Correctly

Position the red focus dot:

-

On the highest point of the curved surface

-

At the center of the engraving area

Then click “Focus” to perform automatic UV laser focusing.

Engraving Transparent Materials?

Place a thin piece of paper on the engraving surface.

UV light can pass through clear material, so this helps the autofocus detect the surface correctly.

7. Check the Wrap and Preview

Before engraving:

-

Use preview to ensure the design wraps around the cylinder correctly

-

Adjust rotation or position to fix misalignment

-

Remove the preview helper when satisfied

This step prevents misprints and saves materials.

8. Start Engraving

Once everything looks right:

-

Click Start

-

Let the rotary chuck rotate the object while the UV laser marks your design

After engraving finishes, wait for the laser to fully stop before removing your workpiece.

9. Review Your Result

Take the engraved item off the chuck and inspect your design.

A properly calibrated setup should give you:

-

Crisp edges

-

Even depth

-

Accurate wraparound alignment

-

Smooth marking across the entire curved surface

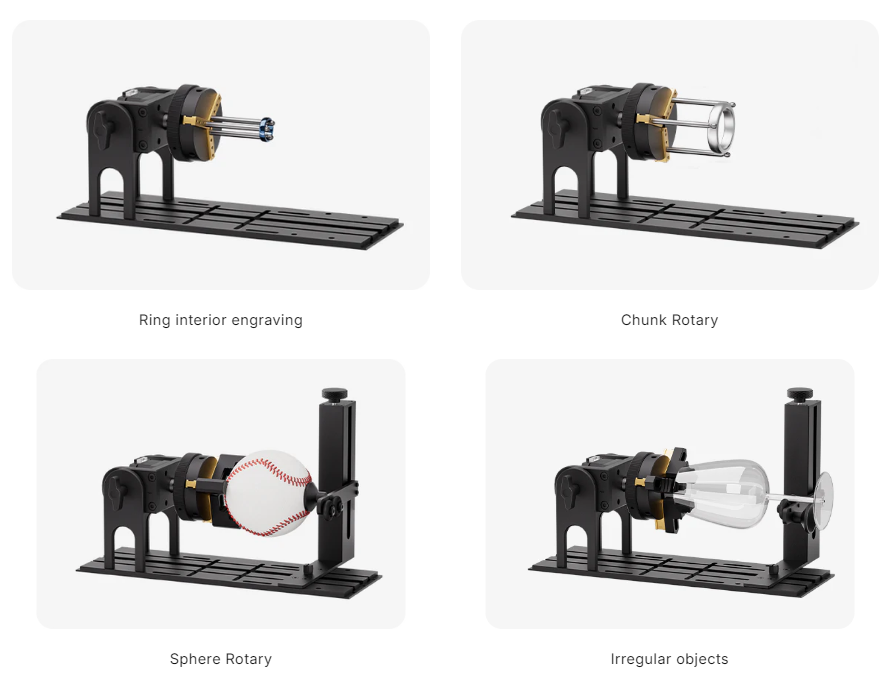

Why Use a Rotary Chuck for UV Laser Engraving?

A rotary chuck gives you flexibility to engrave:

-

Tumblers

-

Rings

-

Pens

-

Curved machine parts

-

Tool handles

-

Small cylindrical components

-

Watch parts

-

Precision industrial items

Paired with a UV laser, it produces extremely fine, high-contrast detail on plastics, metals, coated items, and delicate materials.

Final Thoughts

If you’re looking to expand your laser engraving capabilities, the rotary chuck is one of the most powerful upgrades for the ComMarker UV engraver. It adds precision, versatility, and professional-quality results on curved surfaces—all with a setup process that becomes easy once you follow the correct steps.