Laser engraving on glass can create stunning, precise designs, from intricate patterns to deep, personal engravings. However, working with glass presents some unique challenges, especially when it comes to achieving clarity and focus. Whether you’re a beginner or an experienced engraver, understanding the key steps and techniques for laser engraving glass—particularly with a UV laser—can make all the difference. In this guide, we’ll walk you through the process of glass engraving and share expert tips for working with UV lasers to get the best results.

What is UV Laser Engraving on Glass?

UV laser engraving on glass uses ultraviolet (UV) lasers to etch designs into the surface of the material. UV lasers are particularly effective for glass because they can focus tightly and deliver high precision without causing thermal damage or cracking the glass. This makes them ideal for engraving high-quality, detailed designs on various types of glass, from crystal trophies to decorative glassware.

If you’re wondering how to achieve sharp, detailed results, read on to discover our top tips for laser engraving on glass using a UV laser.

Step-by-Step Guide to Laser Engraving Glass

-

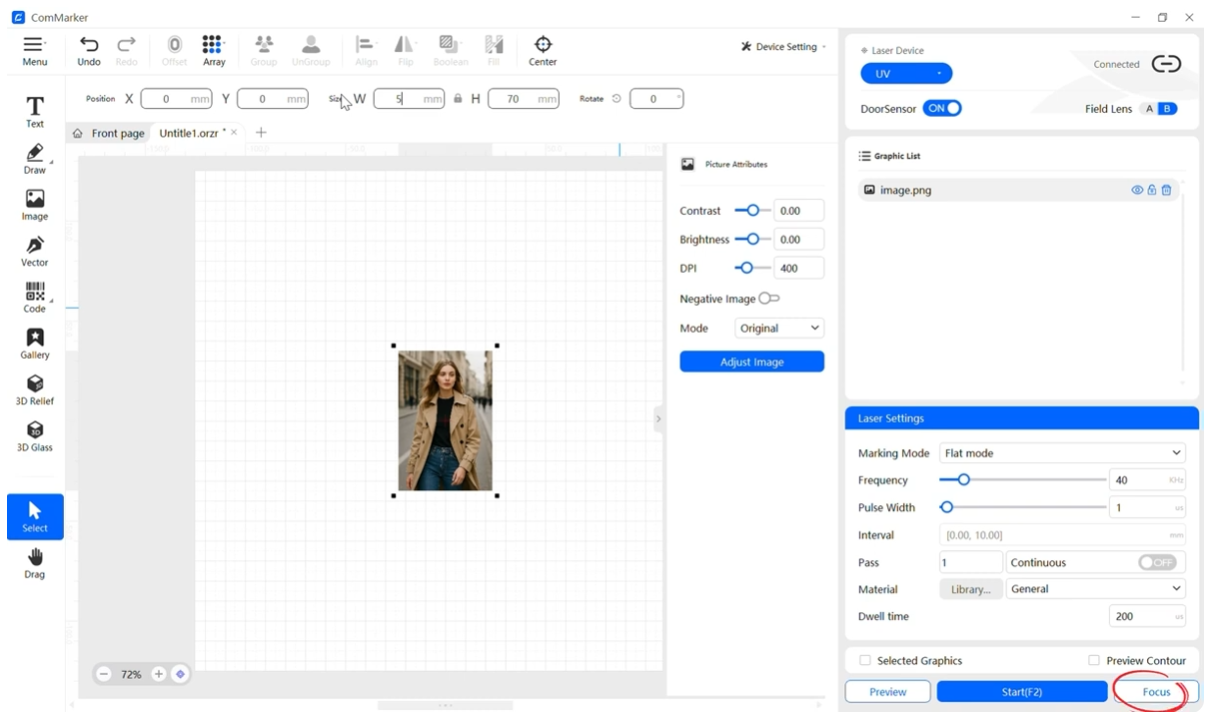

Import Your Design and Set Parameters

The first step in any laser engraving project is to prepare your design. Open your engraving software and import your artwork. Adjust the settings, including engraving speed, power, and resolution. For UV laser engraving on glass, make sure the parameters are optimized to handle the material’s unique optical properties.

-

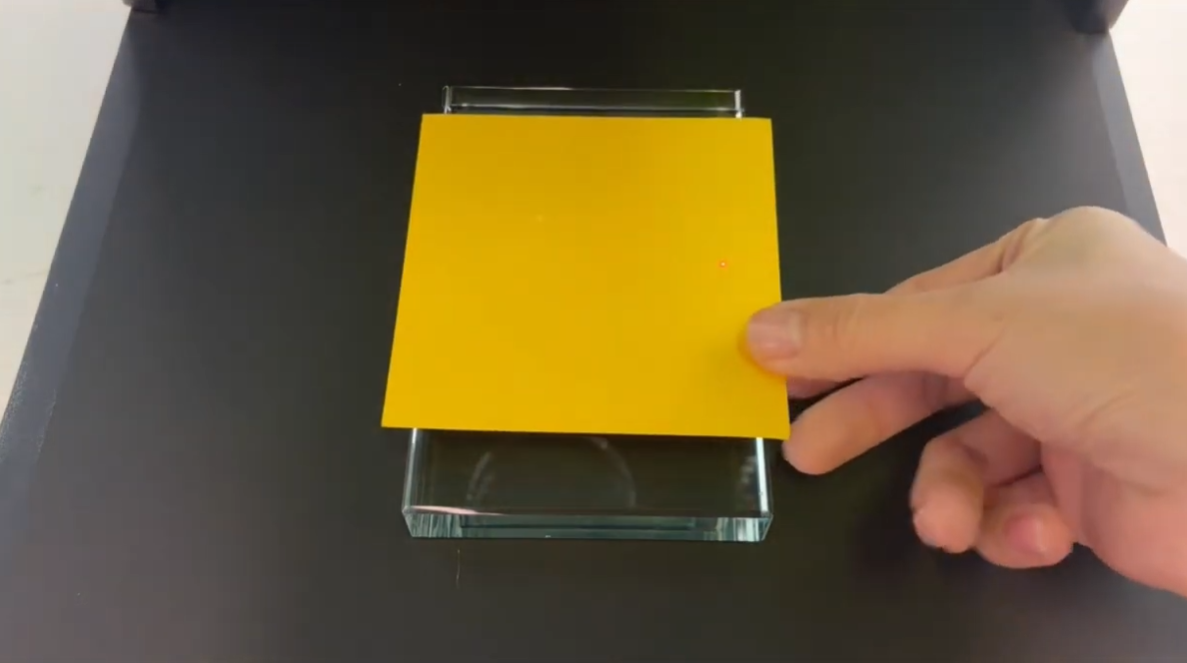

Prepare the Glass Workpiece

Place the glass piece on the engraving bed. If you’re working with clear glass, it’s recommended to place a sheet of paper on top of the engraving surface. This helps the laser focus more accurately and avoids potential issues with transparency.

-

Autofocus for Precision

Click on the autofocus function to allow the machine to find the optimal focal point for engraving. This is a crucial step, as precise focusing ensures clean, sharp engravings. However, keep in mind that some types of glass may have special optical properties that affect the autofocus result.

-

Preview the Design

Once the autofocus is complete, use the preview function to check the size and position of your design. Make sure everything looks good before starting the engraving process. Adjust the placement if necessary to ensure the design fits within the engraving area.

-

Start Engraving

If everything looks good, click “start” to begin the engraving. The UV laser will now etch your design onto the glass. Depending on the complexity of the design, the process may take some time, so be patient as the machine works its magic.

Special Tips for Working with Glass

Understanding Focus Distance for Glass Engraving

Some types of glass have special optical properties, which can affect the true focus distance of the laser. Typically, the actual focus point for certain glass types may be 2 to 3 mm shorter than the autofocus result. This can result in blurred or uneven engravings if not corrected.

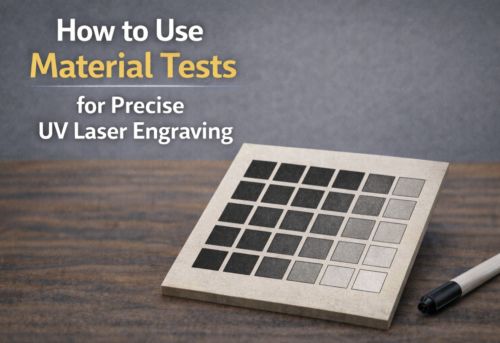

How to Find the True Focus Distance with the Ramp Test

To achieve the sharpest engraving possible, you need to find the true focus distance. Here’s how to perform the ramp test:

-

After performing autofocus, slightly lift one end of the glass to create a slight slope.

-

Engrave a long, straight line across the sloped surface of the glass.

-

You will notice that some parts of the engraving are clearer than others. Measure the distance from the laser head to the spots where the engraving is the sharpest. This will help you identify the true focus point.

For example, if the manual focus distance is 183 mm but the sharpest engraving occurs at 180 mm and 181 mm, you’ll know that the actual focus point is slightly above the autofocus result.

Engraving Inside the Glass

If you want to engrave an image inside the glass (often referred to as “subsurface engraving”), the process is slightly different. First, focus the laser as usual. Then, manually lower the laser head closer to the glass to achieve the desired engraving depth. This technique allows you to create beautiful, three-dimensional engravings inside the glass, giving the design a unique look that can’t be replicated on the surface.

Troubleshooting Common Issues in Glass Engraving

-

Uneven Engraving: If the engraving is blurry or uneven, check the focus distance. The ramp test can help you fine-tune this.

-

Cracking or Shattering: When working with glass, it’s important to adjust the laser’s power to prevent excessive heat buildup, which can cause the glass to crack. A lower power setting is typically best for fine detail work.

-

Inconsistent Depth: Ensure the laser head remains at the correct height and focus throughout the engraving process. Manual adjustments may be needed for subsurface engraving.

Why Use a UV Laser for Glass Engraving?

UV lasers are the preferred choice for engraving glass due to their ability to focus tightly and engrave at high resolution. They also produce less heat compared to CO2 lasers, which reduces the risk of damaging the glass. UV lasers are ideal for engraving intricate details and images, making them perfect for fine art, logos, and personalized designs on glass objects.

Conclusion

Laser engraving on glass using a UV laser can produce beautiful, precise designs that are perfect for both decorative and functional items. By following these tips and techniques, you can achieve professional-level results every time. Whether you’re engraving gifts, awards, or creating custom glass artwork, mastering the UV laser engraving process will allow you to unlock your creativity and produce high-quality engravings with ease.

Got any tips or questions? Feel free to leave a comment below or contact us at [email protected]!