If you’ve ever wanted to personalize stainless steel tumblers, water bottles, or mugs with professional-looking designs, logos, or names, a UV Laser Engraver like the ComMarker Omni X is your best tool.

Tumblers are among the most popular laser engraving projects for beginners and small business owners. They’re perfect for custom gifts, brand merchandise, and promotional items — and the Omni X makes engraving them easier and cleaner than ever before.

In this guide, we’ll walk you through everything you need to know: from choosing the right tumbler type, to setting up your laser, to getting perfect, permanent results every time.

Why Use a UV Laser Engraver for Tumblers?

The Omni X UV Laser Engraver uses a 355 nm cold laser beam, which works through photo-ablation instead of heat. That means it marks the surface of the tumbler with ultra-fine precision — without melting or burning.

Here’s what makes the Omni X a great choice for tumbler engraving:

-

Clean, detailed markings — even for fine text or logos

-

No residue or burning smell

-

Works on stainless steel, coated metal, and plastic tumblers

-

Supports rotary engraving — perfect for curved surfaces

-

Permanent and corrosion-resistant results

Types of Tumblers You Can Engrave

Not all tumblers are made the same. The material and coating type will affect your settings and engraving outcome. Below are the main types of tumblers you can engrave using the Omni X UV Laser Engraver.

1. Stainless Steel Tumblers

This is the most common and beginner-friendly type.

UV lasers remove the outer paint or coating layer to reveal the metal underneath, resulting in crisp, permanent marks.

Recommended Settings:

| Parameter | Value |

|---|---|

| Power | 90–100% |

| Speed | 300–500 mm/s |

| Frequency | 30–40 kHz |

| Pulse Width | 3–6 ns |

| Passes | 1–2 |

Tips:

-

For black or white coated stainless tumblers, start with moderate power and adjust based on contrast.

-

To achieve color marking on bare stainless steel, increase the frequency (200–300 kHz) and fine-tune pulse width — the Omni X’s MOPA UV module allows this precision.

-

Always rotate the tumbler using the Chuck Rotary for even engraving around the surface.

2. Powder-Coated Tumblers

Powder coating is thicker and more heat-resistant than paint.

UV lasers handle it well — they vaporize the coating layer cleanly without melting.

Recommended Settings:

| Parameter | Value |

|---|---|

| Power | 85–95% |

| Speed | 400–600 mm/s |

| Frequency | 30 kHz |

| Pulse Width | 4 ns |

Tips:

-

Focus precisely — powder coatings can scatter UV light if slightly out of focus.

-

If the mark appears faded, reduce speed by 10% for deeper contrast.

-

After engraving, wipe the tumbler gently with a damp cloth to remove any powder residue.

3. Painted Tumblers

Painted metal tumblers are thinly coated, so they engrave easily.

UV lasers remove the paint cleanly, revealing the metallic base layer.

Recommended Settings:

| Parameter | Value |

|---|---|

| Power | 70–85% |

| Speed | 500–800 mm/s |

| Frequency | 25–30 kHz |

| Pulse Width | 2–3 ns |

Tips:

-

Avoid over-powering — high power may damage the metal surface below.

-

For multi-colored designs, experiment with pulse width to produce gradient-like effects.

4. Plastic Tumblers

Plastic tumblers (like acrylic or polycarbonate) are trickier since they melt under heat.

The UV laser’s cold beam, however, allows you to engrave them with minimal surface deformation.

Recommended Settings:

| Parameter | Value |

|---|---|

| Power | 60–70% |

| Speed | 600–800 mm/s |

| Frequency | 20–25 kHz |

| Pulse Width | 2 ns |

Tips:

-

Use a single pass — multiple passes may cause frosting or surface haze.

-

Engrave shallowly for the cleanest look.

-

For transparent plastics, use masking tape to reduce light reflection.

Choosing the Right Rotary Attachment

To engrave tumblers evenly, you’ll need to use a rotary system. The Omni X is compatible with three types:

| Rotary Type | Best For | Description |

|---|---|---|

| Chuck Rotary | Tumblers, mugs, rings | Holds objects firmly by their center — ideal for even engraving around cups. |

| Roller Rotary | Cylindrical bottles | Easy setup, perfect for bulk engraving with uniform shapes. |

| Multi-functional Rotary | Tapered or irregular tumblers | Adjustable angle and grip for non-standard sizes. |

Pro Tip: Always level your tumbler horizontally before engraving. Uneven placement can distort text or images.

Step-by-Step: How to Engrave a Tumbler with the Omni X UV Laser Engraver

Step 1. Design Your Artwork

Use ComMarker Design Room or LightBurn to import your logo or text.

Wrap the design around a circular layout if you want to engrave all around the tumbler.

Step 2. Mount the Tumbler on the Rotary

-

Secure it firmly using the Chuck Rotary.

-

Ensure the surface is level and centered.

-

Plug the rotary into the back of your Omni X and enable rotary mode in software.

Step 3. Focus and Frame

Use Auto LiDAR Focus to set perfect distance.

Run a frame preview to make sure the design lands exactly where you want it.

Step 4. Apply Recommended Settings

Choose the right material preset (stainless, powder-coated, etc.) in the software.

You can also tweak settings manually using the table above.

Step 5. Engrave Your Design

Start engraving and let the rotary turn the tumbler automatically.

Watch through the Omni X’s safety enclosure window — no goggles needed!

Step 6. Clean and Inspect

Once finished, use a soft brush or damp cloth to remove any debris.

If necessary, run a second pass at lower power to deepen the mark.

Troubleshooting Common Tumbler Engraving Issues

| Problem | Cause | Solution |

|---|---|---|

| Engraving too light | Low power or fast speed | Increase power or slow down speed |

| Uneven engraving around tumbler | Rotary not level | Re-level rotary axis and refocus |

| Surface discoloration | Too high frequency | Lower frequency or increase speed |

| Lines not aligned | Incorrect rotary calibration | Reset rotary axis and reframe design |

Expert Tips for Perfect Results

-

Engrave from top to bottom on tapered tumblers for cleaner alignment.

-

Use masking tape for glossy finishes to prevent reflection.

-

Mark your rotary chuck position to ensure consistent repeatability.

-

Avoid multiple passes on coated tumblers — one clean pass usually looks better.

Why the ComMarker Omni X Stands Out

-

True UV Cold Laser (355 nm) — no heat damage or smoke.

-

Built-in LiDAR Autofocus — perfect focus every time.

-

Fully enclosed design — safe for indoor use.

-

Rotary-ready compatibility — supports all major rotary types.

-

Smart software presets — easy for beginners, flexible for pros.

Whether you’re customizing a few gifts or running a small engraving business, the ComMarker Omni X UV Laser Engraver makes tumbler engraving effortless, fast, and fun.

Final Thoughts

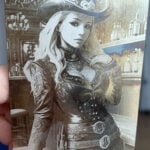

Engraving tumblers is one of the most satisfying and profitable ways to get started with laser engraving.

With the precision and reliability of the ComMarker Omni X UV Laser Engraver, you can create premium, long-lasting designs that stand out — whether you’re customizing one tumbler or producing hundreds.

So grab a blank tumbler, fire up your Omni X, and start engraving your first masterpiece today.