UV laser engraving has quickly become one of the most talked-about technologies in the engraving industry. Unlike diode, CO₂, or fiber lasers, a UV laser engraver offers unmatched precision, cleaner edges, and the ability to mark materials that other lasers struggle with—such as glass, silicon, certain plastics, and coated metals.

To better understand these advantages, this article takes a closer look at how a modern UV laser—such as the Omni X—handles real material tests, 2.5D engravings, and 3D crystal marking. Instead of focusing on a strict product review, we explore what UV laser technology can accomplish and why many creators and businesses are adopting it.

Understanding How UV Lasers Work (and Why They’re Different)

Most laser engravers rely on thermal energy—essentially burning, melting, or vaporizing material.

UV lasers, however, operate at 355 nm, a short-wave ultraviolet wavelength that enables photochemical ablation. Rather than heating the material, the beam breaks molecular bonds directly.

Because of this, UV laser engraving offers several unique benefits:

-

Extremely fine detail with sharp edges

-

Low-heat processing with almost no charring

-

Safe marking on delicate or heat-sensitive surfaces

-

High contrast engraving on coated metals

-

Ability to engrave inside transparent materials like glass or crystal

This makes UV lasers incredibly versatile for both industrial marking and creative applications.

What’s Typically Included With a Modern UV Laser Engraver

Systems like the Omni X often come packaged with a wide range of accessories that expand engraving possibilities. While the exact combination depends on the model, users commonly receive:

-

UV laser engraver base unit

-

70×70 mm and 150×150mm or 250×250 mm field lenses

-

Rotary or chuck modules (To be purchased)

-

Roller attachment for cylindrical objects (To be purchased)

-

Extension table for taller items (To be purchased)

-

Sample materials

-

Safety components and setup tools

These accessories allow a UV laser engraver to handle flat objects, curved surfaces, metal rings, glassware, and even 3D crystal blocks.

Material Tests: What a UV Laser Engraver Can Handle

One of the best ways to understand UV engraving is to look at how it interacts with different materials.

1. Wood

Although UV lasers are not primarily designed for wood, they can still produce clean engravings with strong contrast—especially on images with bold highlights and shadows.

Because the beam produces minimal heat, edges remain crisp without burnt residue.

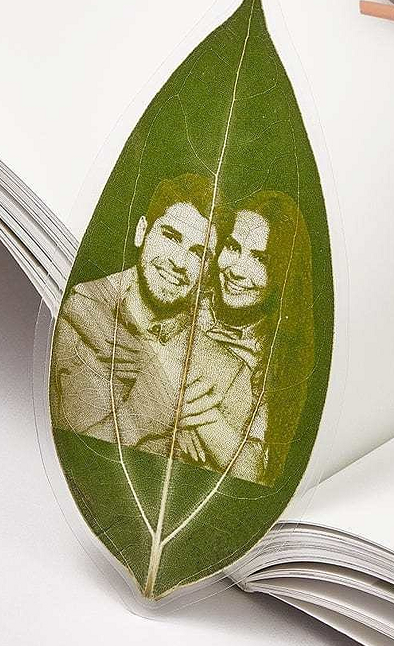

2. Paper and Dried Leaves

This is where UV lasers truly stand out.

Unlike diode or CO₂ lasers, a UV laser can engrave thin paper or dried leaves without burning holes, thanks to its low-heat characteristics.

This opens the door to ultra-delicate artistic engraving.

3. Metals (Aluminum, Copper, Stainless Steel)

UV lasers can mark various metals with excellent clarity:

-

Raw aluminum may require polishing, as oxidation layers reduce contrast.

-

Copper responds well with sharp, high-contrast results.

-

Stainless steel can achieve clean logos and text with minimal passes.

Coated materials—such as anodized or painted aluminum business cards—often produce the highest contrast and most professional finish.

4. Glass and Crystal

One of the signature strengths of UV laser engravers is the ability to engrave inside transparent materials.

UV beams pass through clear surfaces and create micro-fractures at precise depths, enabling:

-

Internal 3D crystal engravings

-

Detailed logos

-

Star signs and decorative patterns

-

High-contrast surface marking on drinkware

This capability is unique to short-wavelength lasers and is commonly used in custom gifts and luxury displays.

Advanced Engraving Modes: 2.5D and 3D Relief

Modern UV laser engravers often include features like 2.5D engraving, which creates textured, layered depth on wood or other compatible materials. This allows for:

-

Raised surfaces

-

Shadowed dimensional effects

-

More sculpted designs than a standard 2D engraving

For clear crystal blocks, 3D internal engraving takes things even further.

By focusing the laser at varying depths, users can create:

-

Characters

-

Logos

-

Miniature sculptures

-

Decorative patterns suspended inside the glass

These internal engravings appear floating and can be extremely detailed due to the fine spot size of UV lasers.

Roller, and Chuck Modules: Engraving Cylindrical Items

UV lasers often support rotating accessories, enabling engraving on:

-

Metal rings and jewelry

-

Tumblers and drinking glasses

-

Curved wooden objects

-

Non-cylindrical items held by a chuck

Accurate alignment is important, especially when working with smaller curved surfaces. However, once set up correctly, rotary engraving produces clean and consistent results.

Strengths and Limitations of UV Laser Engraving

Strengths

-

Exceptional precision

-

Minimal heat impact

-

Ability to mark materials other lasers cannot

-

Excellent performance on metals and coated surfaces

-

Internal crystal engraving capability

-

Clean edges with almost zero residue

Considerations

-

UV laser systems can be heavier due to industrial-grade components

-

Fan noise varies but can be improved with temperature-controlled systems

-

Preview alignment on curved surfaces may require adjustment

-

Larger field lenses reduce detail slightly due to spot size differences

These aren’t drawbacks as much as practical notes to consider when choosing or using a UV laser engraver.

Why Makers and Businesses Consider UV Lasers

UV laser engravers appeal to a wide range of users:

-

Creators who want extremely fine detail

-

Small businesses producing custom glassware, jewelry, or metal goods

-

Industrial users needing durable part marking

-

Gift shops offering engraved crystal products

-

Hobbyists exploring materials impossible for diode or CO₂ lasers

As UV laser technology becomes more accessible, its precision and versatility make it a compelling upgrade.