UV laser engraving is becoming one of the hottest technologies in the personalized gift and customization business, and for good reason.

Operating at a 355 nm short wavelength, UV lasers can deliver ultra‑precise marks on delicate and heat-sensitive materials without burning, warping, or cracking surfaces. Making them perfect for glass, plastics, wood and many other materials.

When people think of UV laser engraving, dramatic 3D crystal inner engraving often comes to mind. Those stunning demos that WOW in posts and marketing videos.

But real users tell a more practical story: In a survey of 51 UV laser owners, only 8 users chose 3D inner engraving glass as a significant use.

Instead, most users choose UV lasers for clean, reliable surface engraving on materials that traditional CO₂ or fiber lasers struggle with. Solving everyday production and customization challenges rather than just creating showpieces.

What Users Are Actually Engraving with ComMarker UV Laser Engraver

- Glass Surface Engraving

No Coatings or Sandblasting Needed (55% mentioned)

28 users out of 51 mentioned glass as their top application.

Common uses:

- Wine and whiskey bottles

- Glass cups and mugs

- Candle jars and cosmetic bottles

- Flat glass awards and plaques

With UV laser engraver, glass can be engraved directly with a fine frosted finish. No sprays, masking films, or sandblasting required. Minimal thermal impact means fewer cracks and more consistent results.

User insight: “Glass is awesome once I worked through the learning curve.”

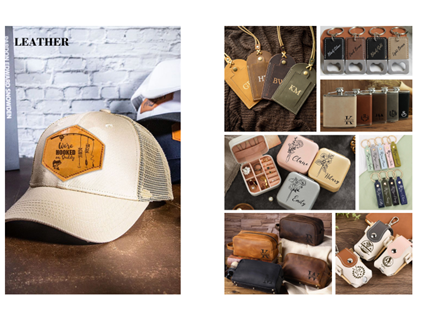

- Leather Engraving

Crisp Marks, Minimal Burn (29% mentioned)

15 users out of 51 picked leather as a key material.

Typical applications:

- Wallets

- Journals and planners

- Patches and labels

- Watch straps and small accessories

Traditional engraving often leaves dark burn marks and heavy smoke residue. UV lasers deliver crisp, clean markings with minimal charring, reducing cleanup time and producing more premium-looking products.

Business benefits:

- Less post-processing

- More consistent results

- Faster turnaround

User insight: “Bought mine for zero char on leather and leatherette goods. Saves time not having to clean soot off every patch, journal, or wallet.”

- Plastics & Acrylic Engraving

Fine Detail Without Heat Damage (22% mentioned)

11 users out of 51 rely on UV lasers for plastic and acrylic.

Applications include:

- Plastic housing and components

- Nameplates and labels

- Transparent or colored acrylic items

UV lasers provide sharp, high-contrast markings without melting or deforming surfaces, making them perfect for:

- Small text

- QR codes

- Fine logos

User insight: “I am here for plastics mostly. UV lets me engrave delicate surfaces without heat damage.”

- Wood Engraving

Cleaner, Sharper Results (18% mentioned)

9 users out of 51 prefer UV lasers for fine-detail wood engraving.

Applications:

- Small fonts

- Decorative patterns

- Craft items, gift boxes, and ornaments

Compared to CO₂ lasers, UV engraving creates less surface charring, cleaner edges, and reduces the need for sanding or cleanup.

What about 3D Inner Engraving?

Creative and Profitable (17% mentioned)

Only 8 users out of 51 mentioned using UV lasers for 3D inner engraving in crystal glass. While visually striking, users consider it:

- A creative add-on

- A showcase feature

- Shines in a market niche

Why Users Prefer UV Lasers Over CO₂ or Fiber

Among the surveyed users, key UV advantages include:

- Better performance on glass (43% mentioned) — high precision without coatings, excellent surface texture

- Cleaner leather engraving (29% mentioned) — minimal burn marks and smoke

- Fine detail & high precision (25% mentioned) — sharp small text and intricate logos

- Low heat / cold processing (18% mentioned) — prevents cracking, warping, or melting

- Wider material compatibility (14% mentioned) — glass, plastics, acrylics, wood, leather

UV lasers are the go-to choice for:

- Direct engraving on heat-sensitive surfaces

- Clean, consistent, high-precision marks

- Minimal post-processing

Other lasers shine in their areas. Fiber lasers for metal engraving, CO₂ lasers for cutting thick non-metals.

But for precision on delicate materials, UV frequently outperforms both.

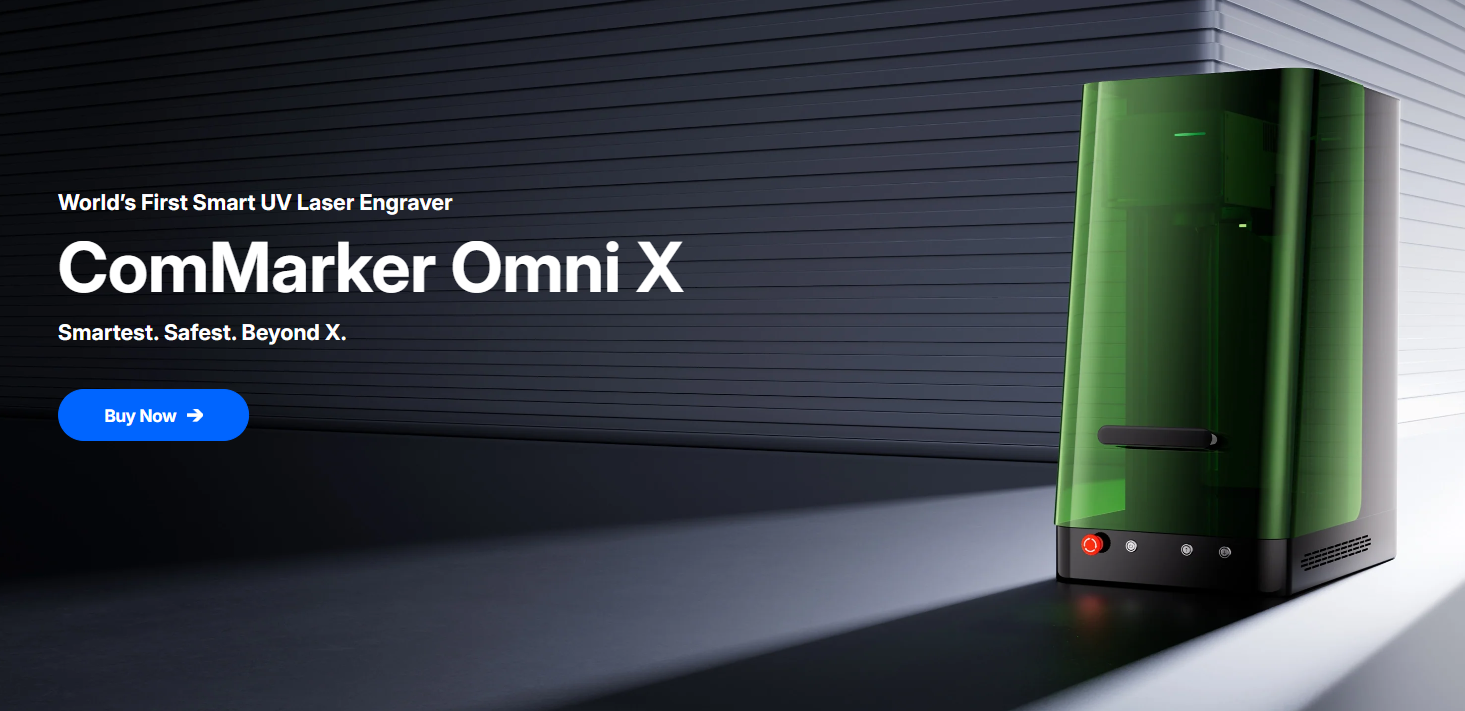

Why Choose ComMarker Omni X UV Lasers

If you want to bring UV laser engraving into your business or creative workflow, ComMarker Omni X UV is the system to trust:

- Proven Industrial Reliability — fully enclosed Class 1 system built from multiple generations of UV laser machines

- Optional 12W Power — choose between 6W and 12W for deeper engraving, faster marking, and industrial workflows

- Flexible Software Options — ComMarker Studio with detailed control, compatible with LightBurn

- Higher Vertical Clearance — up to 235 mm max object height for tall bottles or bulky objects

- Safety First — no laser protective glass required; ideal for schools, workshops, retail, and team environments

- Designed for Real-World Use — perfect for personalization, branding, small-batch production, and fine-detail work

Final thoughts

UV laser engraving is more than a demo trick. Real users rely on it for glass, leather, plastics, and wood.

Creating precise, high-quality products with minimal heat impact and repeatable results. With ComMarker Omni X UV, you get safety, industrial reliability, optional high power, and a proven platform, making it a future-proof investment for small businesses and serious makers.

Ready to start engraving like a pro? ComMarker Omni X UV brings precision, safety, and versatility to your workshop.