If you’re already familiar with UV Laser Engraving, you know it sits in a unique sweet spot:

ultra-clean results, extreme material versatility, and almost zero burn with minimal heat.

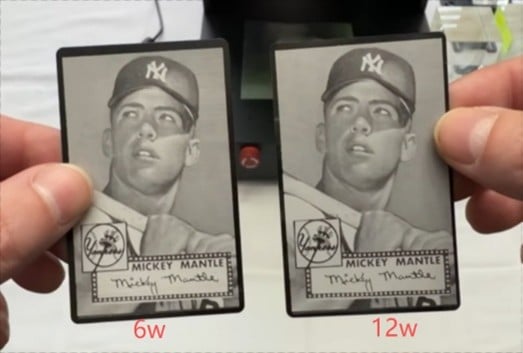

But when it comes to choosing between 6W and 12W, the question becomes simple:

What does 12W UV laser engraver bring you in real-world use?

After hands-on testing with both 6W and 12w of the ComMarker Omni X UV laser engraver, this article breaks down what the 12W UV Laser Engraver truly brings you and who should seriously consider upgrading.

- Same UV Precision — But Faster and More Capable

Let’s clear up a common misconception first:

The 12W UV Laser Engraver does not change what materials you can engrave.

What changes is how efficiently you can engrave them.

Both 6w and 12w UV laser engravers can handle wide range of materials including:

- Metal (aluminum, stainless steel, coated metals)

- Plastic & acrylic

- Glass & crystal

- Wood (without burn marks)

- Leather, fabric, food, leaves, and more

Where the 12W UV Laser Engraver shines is:

- Shorter engraving time

- Deeper engraving when needed

- Brighter glass engraving

- Better consistency at higher speeds

If you’re engraving every day or do batch engraving, speed becomes profit.

- Easy Upgrade Process

If you already have a 6W ComMarker Omni X, the 12W upgrade kit is refreshingly simple.

What’s included:

- 12W UV Laser Engraver module

- UV laser engraver user manual

- Flash drive with software

- Allen keys

- Larger viewing paddle

- 250mm lens (pre-configured)

The full upgrade takes about 15 minutes, and the connectors are all shaped and labeled, so there’s no guesswork.

No firmware headaches.

No mechanical redesign.

- Noticeably Better Results on Engraving Metal (Especially at Speed)

Aluminum & Stainless Steel Engraving

When engraving aluminum with different machines, darker and more defined results were achieved.

Here’s the key takeaway:

With 12W, you can lower dwell time and keep quality.

That means:

- Same darkness

- Less engraving time

- High contrast

On black metal business cards, the 12W ComMarker Omni X:

- Removed visible scan lines seen on 6W

- Produced smoother gradients

- Maintained detail even at faster settings

This is exactly where power matters, not brute force, but clean energy delivery.

- Wood engraving Without Burn or Charring

UV Laser Engravers already outperform other types of laser machines, such as diode and co2 laser engravers on wood when it comes to cleanliness.

But the 12W takes it further.

During 2.5D wood engraving:

- Depth was achieved quickly

- No burn marks

- No charred edges

- Surface looks clean, like it was made by a CNC machine

In fact, the engraving became deep enough that the job had to be stopped early to avoid cutting through the material.

You can either engrave deeper or finish faster. Your choice.

- Metal Coin Engraving: UV Laser Engraver engraver vs fiber laser engraver engraver

Metal coin engraving is usually fiber laser engraver’s strength but testing them on the 12W UV delivered a pleasant surprise.

- Clean, tactile engraving

- Visible ridges

- Subtle, premium finish

Yes, it takes longer than a fiber laser engraver. But the fact that a UV Laser Engraver can even do this, without coatings or sprays, reinforces its capability.

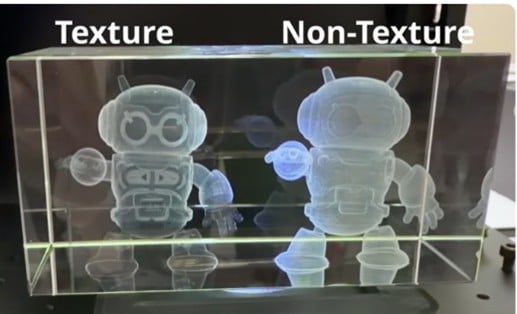

- 3D Subsurface Engraving: Where the 12W Truly Separates Itself

This is where the 12W UV Laser Engraver clearly outperforms the 6W.

Brighter, faster glass engraving with high quality

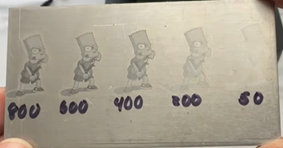

Compared side-by-side:

- Output was noticeably brighter

- More points were filled

- Engraving time was reduced by ~20 minutes per job

For example, a portrait that previously took 1h 40m on 6W:

➡ Finished in 1h 20m on 12W

➡ With better visual impact

Smaller models were engraved even faster, some finishing in just 30–35 minutes.

If crystal engraving is part of your business, 12W isn’t optional, it’s logical.

- UV Laser Engraver Advantage: One Machine, Almost Every Material

This is still the UV Laser Engraver’s biggest strength:

- No marking spray

- No chemical tricks

Compared to diode laser, CO₂, or fiber laser engravers, UV laser engraving and cutting offers:

- Fewer material limitations

- Cleaner surfaces

- More consistent results

- Less trial-and-error

Final Thoughts: Is the 12W UV Laser Engraver Worth It?

Choose 6W if:

- You’re a hobbyist

- You engrave occasionally

- Speed doesn’t matter

- Budget is tight

Choose 12W if:

- You run a business, such as making personalized gifts

- Time = money

- You engrave glass or sensitive materials like wood

- You want stable capability

- You don’t want to upgrade twice

If this is your first UV Laser Engraver and you can afford it, starting with 12W saves money long-term.

If UV engraving is more than just a weekend hobby for you, the answer becomes clear:

The 12W UV Laser Engraver brings efficiency, consistency, and profit.

consistency, and profit.